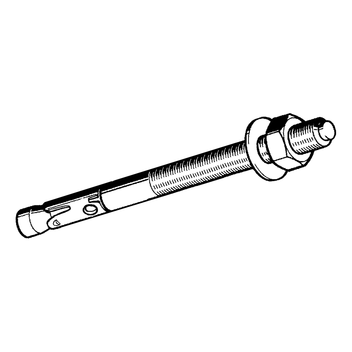

Bolt Anchor AN BZ plus

Application

Anchor for push-through mounting in M&E services and plant construction in concrete tensile zones. This anchor combines high permissible loads with close edge and centre distances.

Suitable for anchoring in cracked and non-cracked concrete - fixation of pipelines, channels, brackets, etc. in closed rooms - except for damp locations.

- No special drill required. Bore dia = thread size

- Simple and quick mounting due to its push-through concept

- Drive-in hammer zone for preventing any thread damage

Scope of delivery

Supplied with washer and hexagon nut.

Installation

| 1. | Drill bore hole according to the minimum bore hole depth perpendicularly to the surface. |

| 2. | Remove dirt from hole. |

| 3. | Drive the anchor into concrete up to its embedment mark. |

| 4. | Immediately resilient after tightening with the torque wrench Tinst indicated in the table below. Advices of the mounting instruction are to be respected! |

Technical Data

Standard anchoring depth:

| Anchor size | M8 | M10 | M12 | M16 |

|---|---|---|---|---|

| Perm. load 1) tension C20/25 2) [kN] | 2.4 | 4.3 | 7.6 | 11.9 |

| C25/30 2) [kN] | 2.7 | 4.8 | 8.5 | 13.3 |

| C30/37 2) [kN] | 2.9 | 5.2 | 9.3 | 14.6 |

| C40/50 2) [kN] | 3.4 | 6.1 | 10.8 | 16.8 |

| C50/60 2) [kN] | 3.8 | 6.8 | 12.0 | 18.8 |

| Perm. load 1) oblique ≥ C20/25 2) [kN] | 7.0 | 11.5 | 17.1 | 30.8 |

| Perm. bending moment 1) [Nm] | 13.1 | 26.9 | 46.9 | 123.4 |

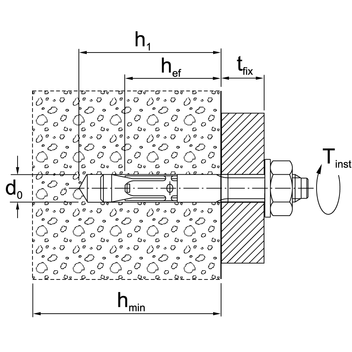

| Min. thickness of component hmin ≥ [mm] | 100 | 120 | 140 | 170 |

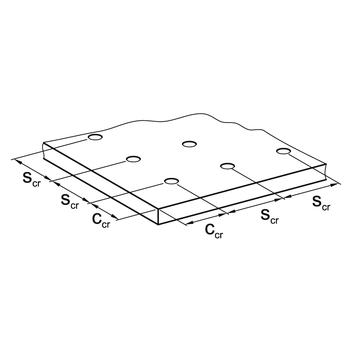

| (3 hef ) Charact. centre distance scr [mm] | 138 | 180 | 210 | 255 |

| (1,5 hef ) Charact. edge distance ccr [mm] | 69 | 90 | 105 | 127.5 |

| Min. centre distance s at/edge distance c ≥ [mm] | 40/70 | 45/70 | 60/100 | 60/100 |

| Min. edge distance c at/centre distance s ≥ [mm] | 40/80 | 45/90 | 60/140 | 60/180 |

| Effective anchoring depth hef [mm] | 46 | 60 | 70 | 85 |

| Nominal diameter of drill d0 [mm] | 8 | 10 | 12 | 16 |

| Depth of bore hole h1 ≥ [mm] | 60 | 75 | 90 | 110 |

| Anchoring torque Tinst [Nm] | 20 | 25 | 45 | 90 |

| Perm. load 3) for fire exposure | ||||

| Perm. load R30 perm. F [kN] | 1.25 | 2.25 | 4.0 | 6.25 |

| Perm. load R60 perm. F [kN] | 1.1 | 1.9 | 3.0 | 5.6 |

| Perm. load R90 perm. F [kN] | 0.8 | 1.4 | 2.4 | 4.4 |

| Perm. load R120 perm. F [kN] | 0.7 | 1.2 | 2.2 | 4.0 |

1) Loads for single anchors without influence of edge distances

2) Cracked concrete (option 1)

3) Edge/Centre distances in case of fire - respective approval is to be respected

Reduced anchoring depth:

| Anchor size | M8 | M10 | M12 | M16 |

|---|---|---|---|---|

| Perm. load 1) tension C20/25 2) [kN] | 2.4 | 3.6 | 5.8 | 8.6 |

| C25/30 2) [kN] | 2.7 | 4.0 | 6.5 | 9.6 |

| C30/37 2) [kN] | 2.9 | 4.4 | 7.1 | 10.5 |

| C40/50 2) [kN] | 3.4 | 5.1 | 8.2 | 12.2 |

| C50/60 2) [kN] | 3.8 | 5.6 | 9.2 | 13.6 |

| Perm. load 1) oblique ≥ C20/25 2) [kN] | 7.0 | 10.0 | 13.9 | 20.6 |

| Perm. bending moment 1) [Nm] | 13.1 | 26.9 | 46.9 | 123.4 |

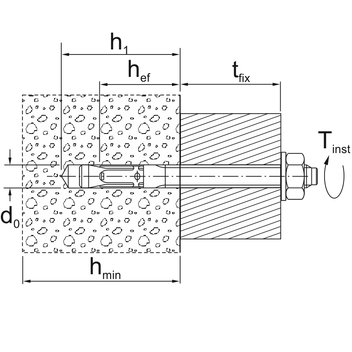

| Min. thickness of component hmin ≥ [mm] | 80 | 80 | 100 | 140 |

| (3 hef ) Charact. centre distance scr [mm] | 105 | 120 | 150 | 195 |

| (1,5 hef ) Charact. edge distance ccr [mm] | 52.5 | 60 | 75 | 97.5 |

| Effective anchoring depth hef [mm] | 35 | 40 | 50 | 65 |

| Nominal diameter of drill d0 [mm] | 8 | 10 | 12 | 16 |

| Depth of bore hole h1 ≥ [mm] | 49 | 55 | 70 | 90 |

| Anchoring torque Tinst [Nm] | 20 | 25 | 45 | 90 |

| Perm. load 3) for fire exposure | ||||

| Perm. load R30 perm. F [kN] | 1.25 | 1.74 | 3.04 | 4.51 |

| Perm. load R60 perm. F [kN] | 1.1 | 1.74 | 3.0 | 4.51 |

| Perm. load R90 perm. F [kN] | 0.8 | 1.3 | 1.9 | 3.5 |

| Perm. load R120 perm. F [kN] | 0.6 | 1.0 | 1.3 | 2.5 |

1) Loads for single anchors without influence of edge distances

2) Cracked concrete (option 1)

Permissible loads according to EN 1992-4 without influence of centre and edge distances. Overall safety factor is taken into account ( YM und YF ). Values of the mentioned approval are valid and could be seen in the latest issue under www.sikla.com/service/downloads.

| Material: | Steel, galvanised |

Approvals / Conformity

Sikla Approval ETA-10/0259

FM-Approval for M10, M12, M16 only for Standard anchoring depth

VdS compliant for all sizes

Shock approval issued by the Federal Office for Civil Defence, Bern (Switzerland)

The types marked * are not part of the Seismic-Approval.

tfix = max. effective length [mm]

ETA 10/0259 PDF | 5.4 MB FM - Sikla Anchors AN PDF | 260.1 KB

The types marked with * are not part of the Seismic approval.

1) Delivery date on request - goods are procured to order.

tfix = max. usable length [mm]