Injection System VMZ - Resin

Application

Resin for Resin Anchor Rod VMZ-A. Excellent load capacity in broken and unbroken concrete. The resin mixture hardens resulting in strong bond with the concrete and a perfectly formed expansion sleeve around the conical rod. The inner bond between the conical rod and the resin mixture is broken by applying a torque moment after the hardening process. The VMZ is approved for use under seismic action according to the performance category C1 and C2 (M10 - M16).

Scope of delivery

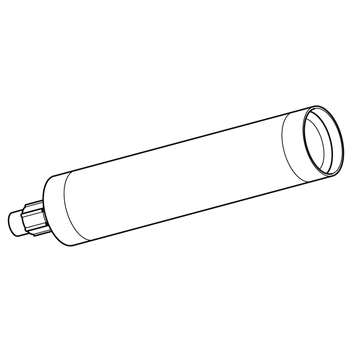

Per cartridge two Mixing Nozzle ANT VM-X are attached.

Installation

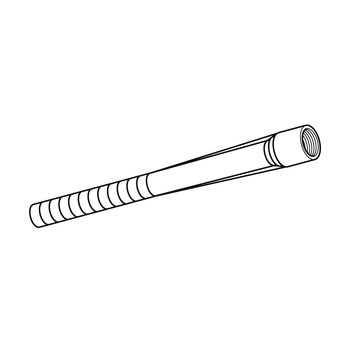

Resin and hardener are separated in the cartridge.

A dispensing tool is used to push both components through a mixing nozzle. In the nozzle the resin and hardener are mixed and filled into the the cleaned drill hole.

After a longer break in work, exchange of the mixing nozzle allows further use of the resin.

Reach of resin:

| Type | Number of drill holes per cartridge |

|---|---|

| VMZ-A M8 ... | 58 |

| VMZ-A M10 ... | 39 |

| VMZ-A M12 ... | 27 |

| VMZ-A M16 ... | 16 |

Technical Data

Detailed technical information could be seen in the data sheets of Resin Anchor Rod VMZ, as well as in the Approval ETA-10/0260.

| Material: | Vinylester basis, styrol-free |

Approvals / Conformity

Sikla Approval ETA-10/0260

ETA 10/0260 PDF | 6.6 MB Fire resistance PDF | 1.1 MB